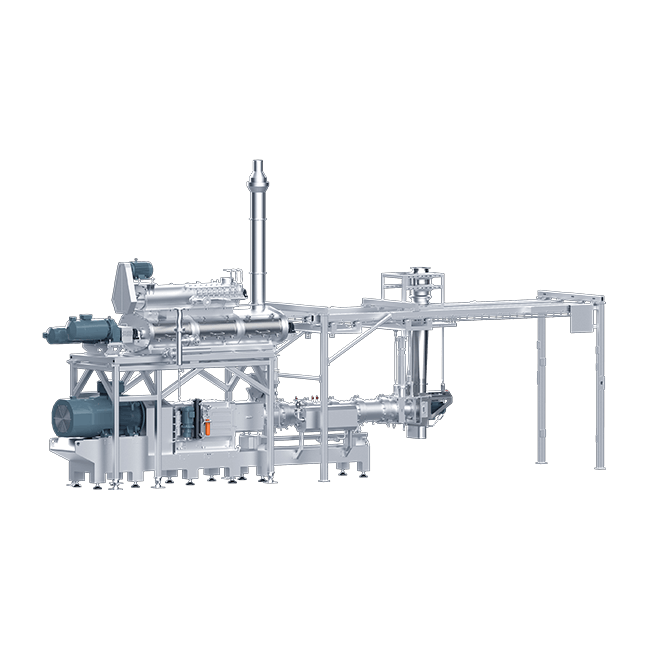

As a leading food extrusion equipment manufacturer, FAMSUN has established itself as a pioneer in the pet food industry. Their twin-screw pet food extruders are designed to deliver a high degree of automation, ensuring consistent product quality and streamlining the production process for pet food manufacturers.

Modular Intelligent Control for Seamless Operations

FAMSUN’s twin-screw pet food extruders feature a modular intelligent control system that allows for independent monitoring of key parameters. This advanced technology enables a high degree of automation, reducing the reliance on manual labor and minimizing the risk of human error.

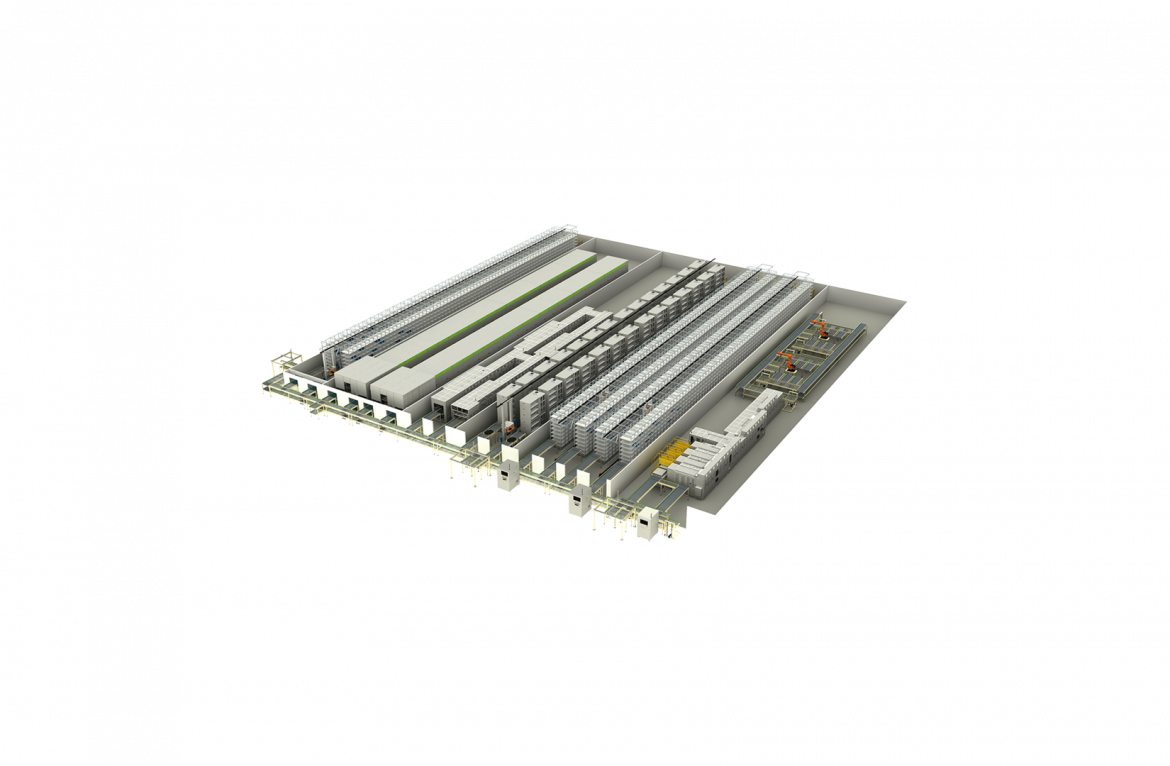

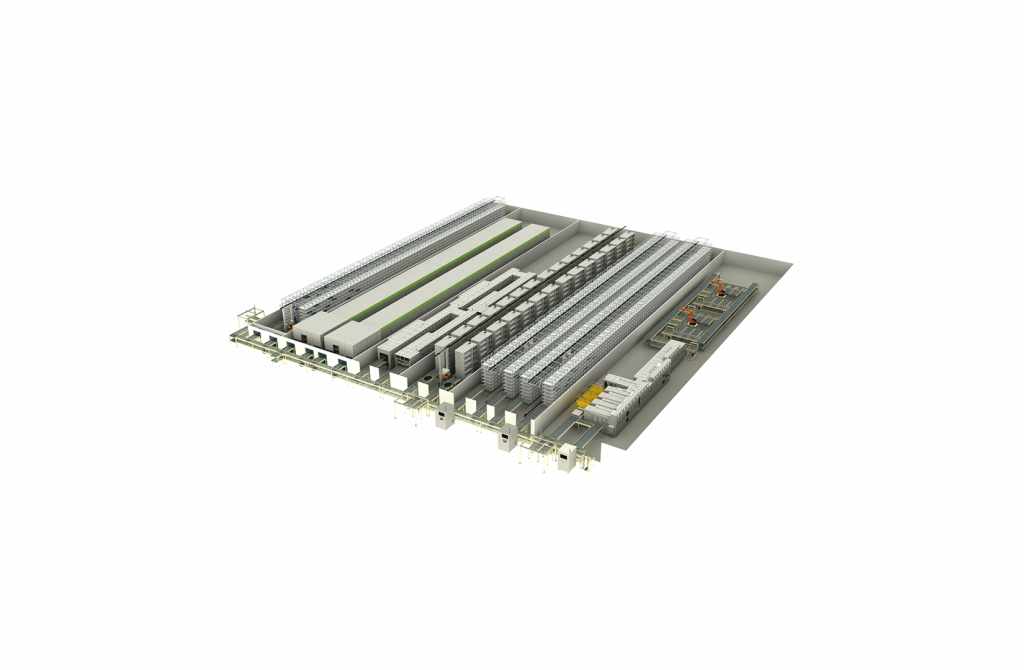

Streamlined Automation for Efficient Production

The pet food extrusion equipment from FAMSUN comes equipped with a suite of standardized modules that enhance the level of automation. These features include automatic system feeding, one-click preheating, one-click conditioning, one-click startup for the extruder and auxiliary equipment, automatic control of mechanical energy, one-click shutdown, and one-click extruder cleaning. By integrating these innovative automation solutions, pet food manufacturers can achieve a seamless and efficient production process, leading to consistent product quality and improved productivity.

Conclusion:

As a leading food extrusion equipment manufacturer, FAMSUN’s commitment to innovation and automation is evident in their twin-screw pet food extruders. By incorporating modular intelligent control and streamlining the production process through advanced automation features, FAMSUN empowers pet food manufacturers to achieve a high degree of efficiency and consistency in their operations. This dedication to technological advancements positions FAMSUN as a trusted partner for pet food producers seeking to elevate their production capabilities and deliver the highest-quality products to pet owners.