Efficient management of materials is a key factor in maintaining seamless production in electronic manufacturing facilities. PassionIOT delivers specialized solutions tailored for SMT production lines, helping businesses streamline operations while enhancing accuracy. Their systems are designed to address a wide range of challenges, including inventory mismanagement, delayed material delivery, excessive manual handling, and difficulties in tracking components. By integrating automated storage and handling technologies, they provide a more organized and reliable production environment, which is critical for companies that aim to meet stringent quality and delivery standards in electronics manufacturing.

Streamlined Material Handling

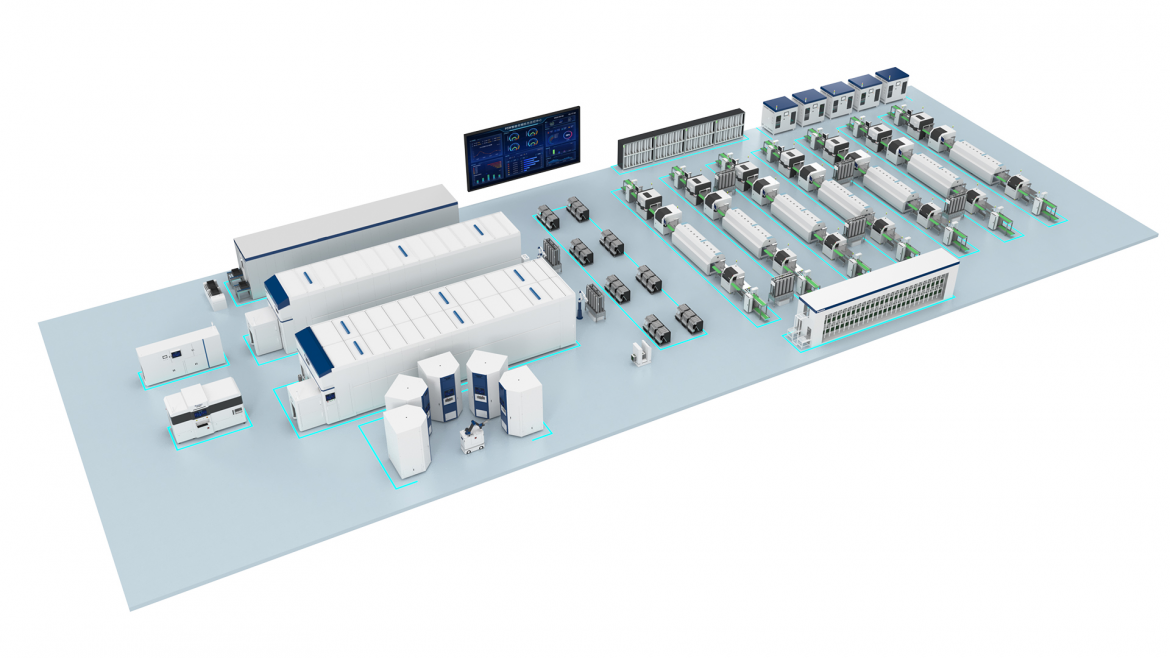

For companies seeking smt material management solutions, they offer integrated systems that automate the storage, retrieval, and delivery of components across production lines. By implementing advanced technologies like the SMD smart warehouse and automated guided vehicles, they ensure that raw materials are readily available at the right time and in the correct quantity. This approach minimizes the risk of human errors, reduces material waste, and provides full traceability for all components. In addition, their solutions can be tailored to accommodate different production layouts, allowing enterprises to maintain flexibility while increasing operational efficiency.

Optimizing Warehouse Logistics

They also focus on improving warehouse logistics, ensuring that materials are stored and retrieved efficiently. Their systems enable real-time communication between storage areas and production lines, providing accurate inventory data and reducing potential downtime. By combining intelligent distribution strategies with automated storage solutions, companies can maximize space utilization and maintain a smooth material flow even during peak production periods. This level of control also supports better planning and coordination across departments, further strengthening the overall manufacturing process.

Conclusion

Overall, PassionIOT helps electronics manufacturers create more predictable, controlled, and efficient operations. Their smt material management solutions and advanced warehouse logistics capabilities reduce labor intensity, improve material traceability, and enhance production accuracy. By adopting these systems, manufacturers can better respond to market demands, optimize resource usage, and maintain consistent output quality. Ultimately, the solutions provided by PassionIOT play a vital role in supporting modern SMT production lines, enabling companies to operate more intelligently and reliably.